HCL Tank Design – Construction Package Project Brief Our Solution The full project scope included: Project Result

The aim of this project was to determine the technicalities of replacing a hydrochloric acid storage tank for a major chemical company based in Bradford. The GRP tank was in disrepair after exceeding its recommended operational design life and needed to be replaced and process safety systems implemented as part of the project.

Our solution was to conduct a Front End Engineering Design (FEED) study supporting the on-site engineering team to ensure that all site specification design standards were adhered to. Once the FEED study was completed, the outcome was to deliver a full design and build CapEx figure for the removal and replacement of the HCL tank and associated systems to include mechanical and electrical decommission and associated material and installation costs.

• New tank and scrubber specification and design.

• Tank sizing, inlet/outlet flange specs.

• Scrubber duty and sizing.

• Structural calculations.

• Steel/gantry supports.

• Process and instrumentation data sheets.

• Level switch/transmitter and valve specs.

• Integration of the new instrumentation into the site DCS.

• Specification of the tanker offload controls and interface into the site control system.

• Line sizing and pressure drop calculations.

• HCL offload and scrubber pipework sizing.

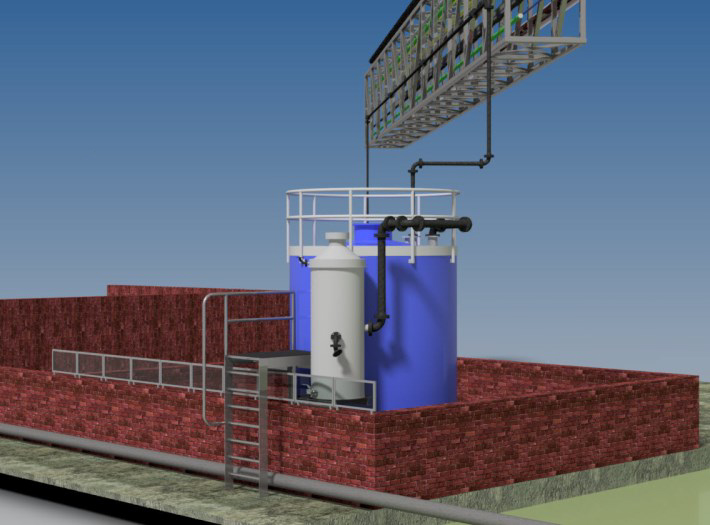

• Detailed 3D model of the entire installation showing the tank, scrubber, pipework, and instrumentation

within the output of piping isometrics, full vessel and scrubber design.

In conclusion this was a successful project taking around 6 weeks from starting to completion. We had different considerations from an engineering point of view such as line sizing, pump sizing and various calculations. The benefits of this project being completed were that the new system adhered to the necessary safety requirements after the ageing site assets were replaced with state of the art equipment.