Project Brief

The aim of this project was to develop a Front-End Engineering Design package and execute through to installation supervision and commissioning of a tank farm, pipe bridge, structural steel platforms, reactors and scrubbers within a chemical process manufacturing facility based in Manchester. This project had been approved to create new product opportunities for the business.

Our Solution

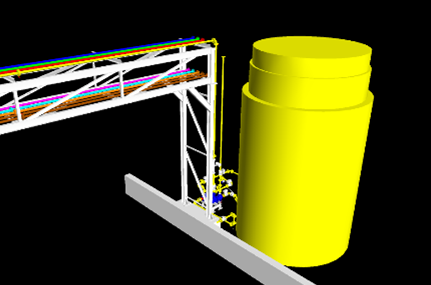

To support our client, we created model concept images using Autodesk inventor and to develop the control philosophy (URS). The process, mechanical and electrical teams then worked together with the client to ensure budgets and timescales were on target for the project and that they were achievable.

The full project scope included:

- P&IDS

- Process description/URS

- Area Layout

- Area Classification

- 3D Modelling

Project Result

In conclusion this was a successful project taking around 52 weeks from starting to completion. We had numerous applications and to implement, covering hazardous areas (IEC60079), storage of flammable products (HSG176) and bund design to CIRIA 736. Following the completion of the project the client had increased operational capacity and functionality to deliver their product portfolio in a more efficient and timely manner.